Mar 27, 2025

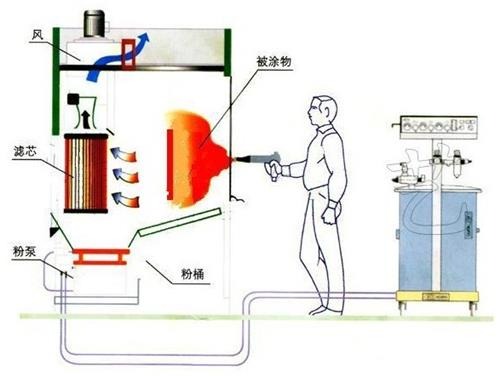

With the advancement of Industry 4.0,automation technology of electrostatic spraying is reshaping the production pattern at an unprecedented speed. The automated electrostatic spraying system, relying on its characteristics of high efficiency, precision and stability, is becoming a key factor for numerous manufacturing enterprises to enhance their competitiveness.

The automated electrostatic spraying production line has realized the full-process automated electrostatic spraying operations from workpiece transportation, spraying to quality inspection. Through advanced robotic technology, spraying robots can conduct precise spraying according to preset trajectories and parameters, ensuring that each workpiece can obtain a consistent coating effect. Compared with manual spraying, robot spraying is faster and there will be no fluctuations in spraying quality due to fatigue. For example, in large automobile manufacturing factories, the automated electrostatic spraying production line can complete the spraying work of a large number of vehicle bodies in a short time, and the error of coating thickness can be controlled within a very small range, which greatly improves the production efficiency and the stability of product quality.

In addition, the automated electrostatic spraying system also has a high degree of flexibility. By adjusting the program, it can meet the spraying requirements of workpieces with different shapes and sizes and achieve coating for diversified products. This enables enterprises to respond quickly to market changes and produce diversified products. In the field of 3C product manufacturing, automated electrostatic spraying equipment can accurately adjust the spraying path according to the shapes of the casings of different models of mobile phones and tablets to realize personalized coating operations.

Automated electrostatic spraying is also deeply integrated with the intelligent control system to achieve intelligent production management. Various data in the production process, such as the amount of paint used, spraying speed, coating thickness, etc., can be monitored and analyzed in real time. Once an abnormality occurs, the system will immediately issue an alarm and automatically adjust to realize the intelligent management of the production process. This not only improves production efficiency but also enables the timely detection of potential quality problems and reduces production costs.

With the continuous development and improvement of the automation technology of electrostatic spraying, it will be widely applied in more industries, bringing higher production benefits and better products for enterprises and leading the manufacturing industry to a new stage of development.

Read More